28, 46019

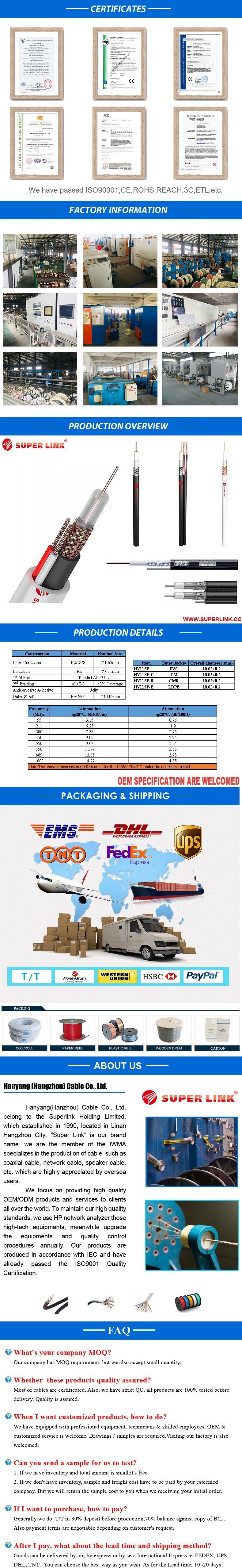

Business Type:

Manufacturer/Factory & Trading Company

Business Range:

ACSR,AAAC,AAC,ABC Cable,Electrical Cable,Electric ,

Management System Certification:

Terms of Payment:

LC, T/T, D/P, PayPal, Western Union, Small-amount

OEM/ODM Availability:

Yes

Trial Member

4 years

Audited Supplier