| Purchase Qty. / Reference FOB Price | |

|---|---|

| 45 square meter | US $43 |

| 1000 square meter | US $26 |

| Production Capacity: | 58420 |

|---|---|

| Payment Terms: |

Tianjin exports color steel houses for engineering use in the United States

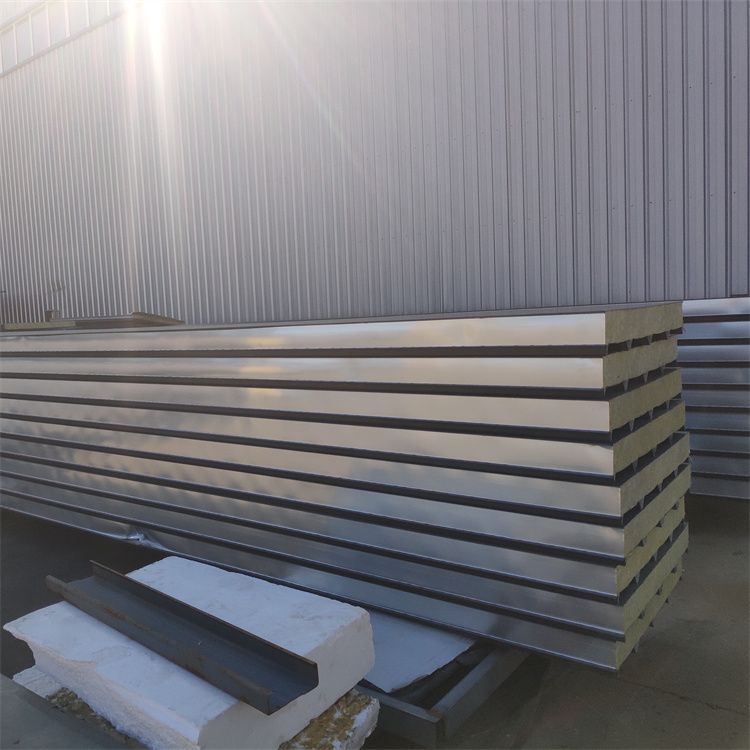

As we all know, color steel houses are composed of color steel plates and steel structural frames. Steel structure frames are generally made of light steel structures, welded into rectangles, with roofs or sloping roofs or two-sided slopes, etc. However, with the needs of development, many special-shaped color steel houses have emerged, such as one end large and one end small color steel houses, "convex" or "concave" shaped color steel houses, L-shaped color steel houses, asymmetric L-shaped color steel houses, and so on. This requires us to be doubly careful and sincere in our design and installation. Due to its irregular size, many unconventional construction welding methods have been created. So when designing and building special-shaped color steel houses, special-shaped activity houses, and construction site activity houses, it is important to pay attention to selecting people who are proficient in the production, manufacturing, and installation of color steel houses, activity houses, container houses, steel structures, etc., in order to avoid many unnecessary troubles.

Tianjin exports color steel houses for engineering use in the United States

In the field of color steel, it can be said that we are very familiar with it. Color steel is simply a combination of steel keel and sheet metal. Container houses, color steel houses, and activity houses are all like this. Why are these three types of houses designed differently? Container houses need to be lifted, and in addition to reinforcing the skeleton, the panels also need to be sturdy. Therefore, most of the panels are made into corrugated shapes to ensure firmness and waterproof insulation. Color steel houses are made by welding the skeleton and cutting the panels on site, so for the convenience of installation, the panels are attached to the outside of the skeleton for installation. Activity rooms are different from the two mentioned above. In order to achieve effective construction of temporary buildings on construction sites, the skeleton of the activity room needs to be processed according to certain rules at home, and the boards need to be cut according to a certain modulus. There is basically no need for secondary processing when it comes to the site, and it can be installed directly. So can you tell the difference between these three from the production process?

Contact Us | User Agreement | Privacy Policy | 加入会员

Service Tel: (+86)0571-87774297