Product Advantages

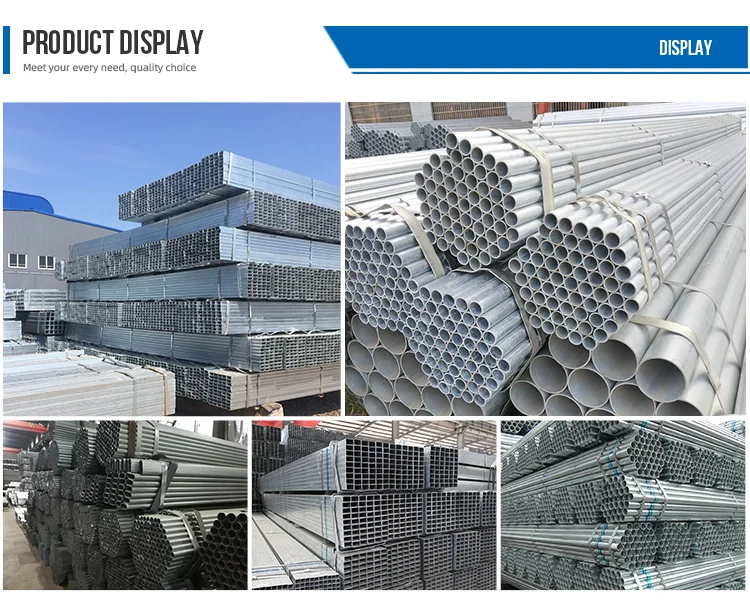

Galvanized steel pipes have good structural strength and compression and impact resistance. They can adapt to various complex environments and have a wide range of applications. They can be used in fire protection, gas, water supply and drainage and other fields. They are economical, practical and reliable pipes.

9684, 46019

Business Type:

Business Range:

Galvanized steel pipe,

Management System Certification:

Terms of Payment:

OEM/ODM Availability:

Industrial cloud member

11 years

Audited Supplier